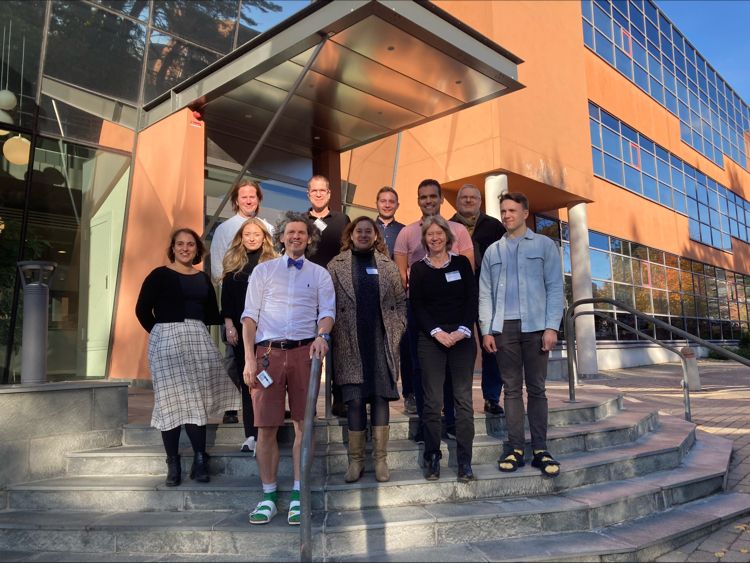

The Swedish online magazine Elektroniktidningen recently published an article about the B-BRIGHTER project.

“It takes no more than ten minutes to produce a 10x10x1 millimetre piece of tissue from a hydrogel mixed with stem cells and MYCRONIC’s laser system drawing the structure. The next phase of the EU B-BRIGHTER project will be to bring the technology one step closer to a commercial product”. This is how the article about the B-BRIGHTER innovative 3D bioprint technology published the 12th of January on “Elektroniktidningen” begins. This online magazine provides the Swedish electronics industry with qualified news, analyses, and in-depth technical articles. They also have a website in Finland.

The article highlights the advantages of this new technology to produce bioprinted human tissues over what exists nowadays: “Creating living tissues is a relatively new area where capillary dispensing has been used to build layer after layer from the bone upwards. With laser technology it is possible to do the opposite and build freely in space in the hydrogel. It is also much faster, meaning that a higher proportion of cells are still alive when the tissue is complete”.

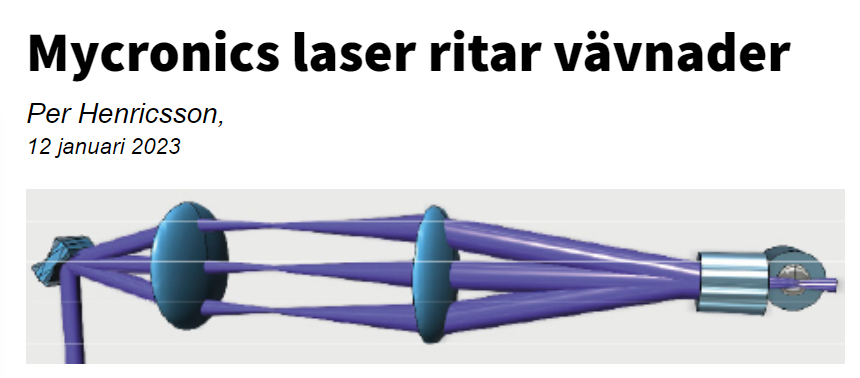

In B-BRIGHTER technology, an acousto-optic technique is a key element. It is used to control the light from the laser and consists of two parts, one that affects the intensity of the light and one that affects the direction. “Starting with a 3D cad of the object to be manufactured, it is converted into voxels, each of which has a position and an intensity. It is possible to create any pattern, says Robert Eklund at MYCRONIC.

The initial project (named BRIGHTER) was funded with almost 3 million € by the EU, while the continuation, the B-BRIGHTER project, has received more that 1,5 million € for creating a product that can manufacture tissues and bring it closer to the market. In the actual phase, researchers are trying to make different types of tissues including skin, cornea and intestine, all of which have their characteristic shapes.

The article also emphasizes that the system will not only produce tissues, but by using a separate laser it will also be possible to see what is happening in real time.

You can read the original article in this link.

The Swedish online magazine Elektroniktidningen recently published an article about the B-BRIGHTER project.