Bioprinting is considered the most promising method to produce functional engineered tissues with physiological properties. Successful tissue engineering will open research avenues for drug testing and therapeutic and will therefore raise much interest not only in academia, but also the pharmaceutical and clinical sectors.

Current bioprinting methods are limited by combinations of insufficient speed, spatial resolution and cell viability. Moreover, the current technologies typically lack the control of tissue biomechanical properties, and consequently, the reconstituted tissues fail to mimic the heterogeneous and physiological nature of native tissues.

B-BRIGHTER OBJECTIVE

B-BRIGHTER will develop a novel bioprinting technology able to produce engineered tissues with high spatial resolution at high printing speed using an original top-down lithography approach. In contrast with current bottom up, layer-by-layer bioprinting methods, B-BRIGHTER aims at ultrahigh-speed digital light-sheet illumination strategy to selectively photo-crosslink cell-laden hydrogels mimicking specific tissues, in confined voxels and produce three-dimensional complex geometries. B-BRIGHTER also has a specific focus on establishing a business case for the light-based bioprinter.

This radically new bioprinting technology aims to boost the performance of various engineered tissues which in turn will promote improved healthcare opportunities, as well as business and employment advances in the European Union and beyond.

BRIGHTER -> B-BRIGHTER

B-BRIGHTER will give continuity to the previous BRIGHTER project taking profit of the knowledge and know-how generated in the field of light-sheet bioprinting. The advances of BRIGHTER will be extended here by building complex bioengineered skin, cornea and gut tissue models, all of which represent pioneering examples for bioengineering, and its application for cell therapy, drug discovery and toxicology. Together with the work on patterning technology, bioink and application, a basis will be established for formulating a valid business case for a bioprinting product.

The work on exploitation activities will ultimately result in a go-no go decision for the industrialisation of a bioprinting product and a commercial path forward.

“The goal of the B-BRIGHTER project is to provide close-to-market demonstrator of the Light-sheet Bioprinter device together with a set of validated bioinks and bioprinting protocols. Aiming to achieve TRL5, B-BRIGTHER will test the developed technology in a relevant final user environment showcasing three complex tissues: the skin, the gut and the cornea.”

TECHNOLOGY AND PROOF-OF-CONCEPT

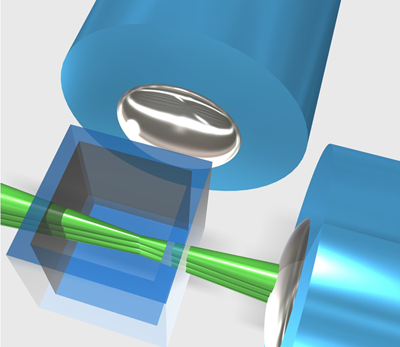

A hydrogel composed of living cells and photosensitive molecules is deposited in a special cuvette. A thin laser light sheet illuminates the gel following a programmed pattern (green beam). This leads to the formation of 3D micro-structures that reproduce the tissue architecture and function. The remaining, still liquid hydrogel is washed out after the printing process.

A hydrogel composed of living cells and photosensitive molecules is deposited in a special cuvette. A thin laser light sheet illuminates the gel following a programmed pattern (green beam). This leads to the formation of 3D micro-structures that reproduce the tissue architecture and function. The remaining, still liquid hydrogel is washed out after the printing process.

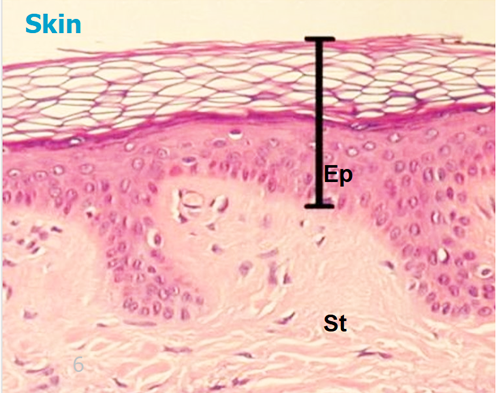

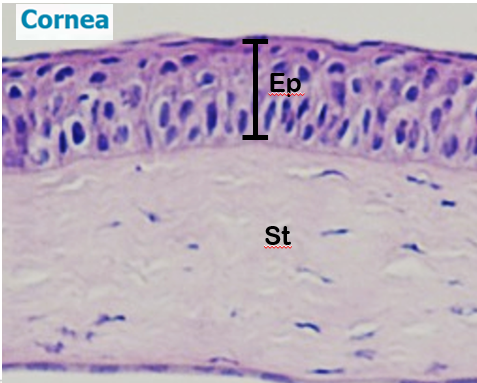

B-BRIGHTER will feature three complex tissues to test the new technology: the skin, the gut and the . All of them are barrier tissues that protect the body from pathogens, toxic substances and environmental stresses. The functionality of bioprinted tissues will be evaluated through morphological and barrier function tests.

Bioengineering complex tissues

- Pioneering stem cell-based therapies

- Large interest in academia, industry (cosmetics) and clínica (drug discovery, grafting)

Advantages

- Extremely high cell viability extremely low cell toxicity

- Stem cell friendly ECM and niches

- Tuneable niche biomechanics

- High reproducibility

Bioengineering steps

- Tuneable stroma formation

- Basement membrane

- Epithelial stem cells

This novel approach will make for the first-time high resolution fully compatible with high speed in a bioprinting process.

This will lead to constructs that will faithfully mimic the heterogeneous architecture, biochemical and mechanical properties of cell microenvironment within tissues without compromising cell viability due to long bioprinting periods.

B-BRIGHTER technology will enable the bioprinting of key anatomical microfeatures of tissue such as invaginations, evaginations or wavy morphologies. It will also incorporate hollow vascular structures while maintaining tissue mechanical integrity without the need of additional sacrificial material. As a remarkable feature, matrix crosslinking density can be fine-tuned using B-BRIGHTER’s approach, allowing the fabrication of cellular compartments requiring specific matrix stiffness such as stem cell niches.

Such capabilities open new venues in the bioprinting of complex tissues with their anatomical microfeatures and incorporating specific matrix properties to compartmentalize cells and/or allow vascularization.

MAIN OBJECTIVES

- Further refining and engineering the Light-Sheet Bioprinter prototype and the bioinks developed in BRIGHTER project.

- Building 3D complex structures in cell-laden hydrogels.

- Proof-of-concept: engineering complex barrier tissues models (skin, cornea and gut).

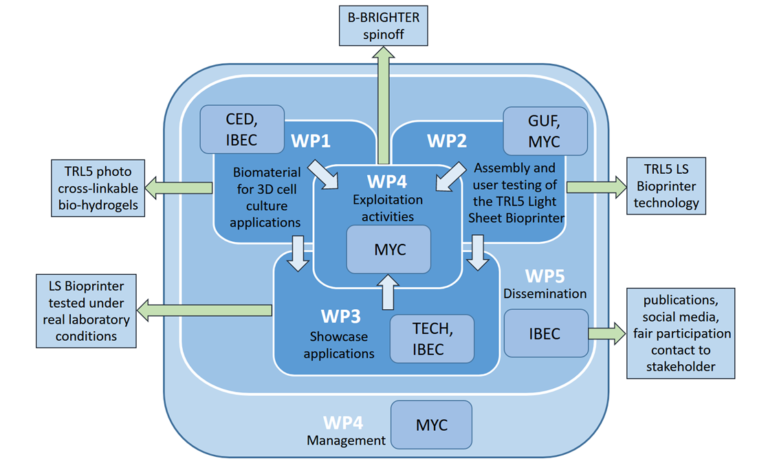

B-BRIGHTER WORKFLOW

CONSORTIUM

![]()

MYCRONIC AB, Sweden

NYTORPSVÄGEN, 9, Täby 183 03

PROJECT COORDINATOR

Department carrying out the proposed work:

Technology Development/R&D, Nytorpsvägen 9, Täby, 183 03 Sweden

Person in charge of the proposal:

Gustaf Mårtensson · gustaf.martensson@mycronic.com

Expert Complex Fluids

Gustaf Mårtensson |

Robert Eklund |

Pontus Stenström |

Martin Glimtoft |

Mycronic is a Swedish high-tech company that has been active in the electronics industry for more than 30 years. The global organization with subsidiaries, agents and distributors supports industry leaders in more than 50 countries. The global footprint ensures that Mycronic has a deep market understanding and can provide rapid support for all their customers who rely on an efficient production. The company has above 900 employees, 450 patents, and more than 2500 customers. Mycronic creates world-leading production equipment for electronics and display manufacturing. Headquarters in Täby, north of Stockholm, Sweden. Local presence in more than 50 countries. 25% of the workforce in R&D. Wholly owned subsidiaries in China, France, Germany, Japan, Singapore, South Korea, Taiwan, the Netherlands, the United Kingdom and the United States. Owner of Shenzhen Axxon Automation Co., Ltd (80%), Automation Engineering, Inc. (100%), RoyoTech Digitalelektronik GmbH (100%) and Vi TECHNOLOGY S.A.S (100%). Listed on NASDAQ, Stockholm, Mid Cap. Certified to ISO 9001:2015/ ISO 14001:2015

For producers of advanced flat screen displays, the Mycronic technology is indispensable. The same holds true for some of the most agile and responsive circuit board manufacturers, who use Mycronic machines to produce a wide variety of the most complex boards in the world. And the automotive industry use Mycronic’s fully automated production systems to assemble and test the camera modules used in Advanced Driver Assistance Systems (ADAS) in today’s and tomorrow´s cars. The heavy investments in R&D is an indication of Mycronic’s commitment to continuous innovation.

Role in the project

Mycronic is the coordinator of B-BRIGHTER project and will provide knowledge and manpower for system design for pattern generators as well as for pattern generator optics, servo, data channel and system control software. Digital photomasks will be used to generate patterned light sheet. The patterning is obtained by integrating in the DSLM the advanced acousto-optic modulator (AOM) system by Mycronic, which combines high resolution with short writing times. A dedicated data channel and control software will need to be developed. What Mycronic brings to B-BRIGHTER is a long experience in developing high precision optical pattern generators.

FUNDACIO INSTITUT DE BIOENGINYERIA DE CATALUNYA, Spain

CARRER BALDIRI REIXAC PLANTA 2A 10-12, Barcelona 08028

Department carrying out the proposed work:

Biomimetic systems for cell engineering group

CARRER BALDIRI REIXAC 15-21, 08028 Barcelona

Person in charge of the proposal:

Elena Martínez · emartinez@ibecbarcelona.eu

Group leader, Biomimetic systems for cell engineering group

Dr. Elena Martínez |

Dr. Núria Torras |

Dr. Marcel Sorribas |

Angela Cirulli |

The Institute for Bioengineering of Catalonia (IBEC) is a research institute covering most bioengineering fields, from basic research to medical applications, aiming to act as an international reference in this field. The institute has also established close links with international research centres, universities, hospitals and industry to exchange talent, and develop and execute projects. IBEC was established in 2005 by the Government of Catalonia, the University of Barcelona (UB) and the Technical University of Catalonia (UPC) and is located at the Barcelona Science Park (PCB, www.pcb.ub.eduwww.ibecbarcelona.eu/biomsyscelleng) sharing also facilities with the Bellvitge University Hospital (BUH). IBEC hosts around 250 researchers and technicians, which are part of its own staff or are associated to the UB and UPC or coming from different recruitment programs of research staff (e.g. ICREA and others). Within IBEC, the “Biomimetic Systems for Cell Engineering” group, headed by Dr. Elena Martínez is a multidisciplinary research group focusing its research activities on the development and application of new artificial systems that mimic tissue micro- and nano-features for more biomimetic in vitro assays. Within this field, the specific research lines are: i) development of new nano-patterned surfaces that allow for the study of ligand clustering on receptor signalling, ii) development of new techniques to microstructure hydrogels for the fabrication of biomimetic epithelial barriers, iii) fabrication and application of gradient surfaces and iv) fabrication and application of mini-bioreactors that incorporate multiple signalling (mechanical, chemical and electrical) to stem cells for cardiac differentiation. Moreover, the group has established several fruitful collaborations at the national and international level, including, Dra. Margarita Calonge (University de Valladolid), Dra. Núria Montserrat (CMRB), Prof. Angel Raya (CMRB), Dr. Matthew Dalby (University of Glasgow), Prof. Daniel Riveline (University of Strasbourg), Dr. Eileen Gentelman (King’s College London), Prof. Molly Stevens (Imperial College London), Prof. François Rossi (JRC Ispra) and Prof. Vasco Teixeira (University of Minho).

Role in the project

IBEC group is a multidisciplinary research group focusing its research activities on the development and application of nanotechnology to the development of new artificial systems that mimic tissue micro- and nano-features for more biomimetic in vitro assays.

IBEC will participate in workpackages 1, 3 and 5, contributing to provide feedback and assessment for the optimization of the photo-crosslinkable bio-hydrogels to be suitable for the applications indented in B-BRIGHTER project. IBEC will also be part of the showcase of the developed B-BRIGHTER light-sheet bioprinter, testing its applicability for developing gut 3D models.

JOHANN WOLFGANG GOETHE-UNIVERSITATFRANKFURT AM MAIN, Germany

THEODOR W ADORNO PLATZ 1, Frankfurt AM MAIN 60629

Department carrying out the proposed work:

Physical Biology, Max-von-Laue-Str. 15, Frankfurt am Main, D-60438 Germany

Person in charge of the proposal:

Francesco Pampaloni · fpampalo@bio.uni-frankfurt.de

Group leader, Physical Biology group

|  |  |

| Dr. Francesco Pampaloni Principal Investigator fpampalo@bio.uni-frankfurt.de | Louise Breideband PhD student breideband@bio.uni-frankfurt.de | Levin Hafa PhD student hafa@bio.uni-frankfurt.de |

The Goethe University Frankfurt (GUF) is a research-oriented university in the European financial centre Frankfurt founded in 1914 with purely private funds by liberally-oriented Frankfurt citizens, it is dedicated to research and education under the motto “Science for Society” and to this day continues to function as a “citizens’ university”. Many of the early benefactors were Jewish. Over the past 100 years, Goethe University has done pioneering work in the social and sociological sciences, chemistry, quantum physics, brain research and labour law. It gained a unique level of autonomy on 1 January 2008 by returning to its historic roots as a privately funded university. Today, it is among the top ten in external funding and among the top three largest universities in Germany, with three clusters of excellence in medicine, life sciences and the humanities.

The Buchmann Institute for Molecular Life Sciences (BMLS) was founded in 2009 at Goethe University Frankfurt as part of the Cluster of Excellence Frankfurt Molecular Complexes. The focus of the institute is understanding the molecular mechanisms underlying cellular functions. The Institute is composed of twelve scientific groups from various disciplines including biology, physics, chemistry, and medicine.

A major goal of the Physical Biology Group (http://www.physikalischebiologie.de/) is to pursue experiments in the life sciences under close-to-natural conditions and to quantitatively evaluate the results. To this aim, we develop innovative fluorescence microscopes. The group has pioneered the application of Light Sheet Fluorescence Microscopy in cell and developmental biology. We employ physiologically relevant cellular models for both fundamental and applied as well as translational research. We collaborated with major industrial partners (Bayer -Berlin, Lonza -Maastricht, Zeiss -Jena) and smaller biotechnology companies (Spherotec, München; Insphero, Switzerland) as well as with academic partners at the Max-Planck-Institutes for Cell Biology and Genetics (Dresden) and for Brain Research (Frankfurt am Main) and the Goethe University Clinics. We have employed cellular spheroids as models for the development of healthy tissues as well as models for tumor growth. We investigate stem cell pancreas organoids for the cellular therapy of Diabetes Type 1 (project EU Horizon2020 project LSFM4LIFE) and liver tumor organoids for cancer personalized medicine (InnoSysTox Grant, project Onconoid Hub).

Role in the project

GUF will be in charge or workpackage 2, performing the assembly and user testing of the B-BRIGHTER light-sheet bioprinter and the preparation of standardized specimen preparation kits to use in combination with the light-sheet bioprinter.

CELLENDES GMBH, Germany

Gerhard-Kindler-Strasse 8, Reutlingen 72770

Department carrying out the proposed work:

Research & Development department

Gerhard-Kindler-Strasse 8, Reutlingen 72770

Person in charge of the proposal:

Helmut Wurst · helmut.wurst@cellendes.com

Executive Manager, Research & Development department

Helmut Wurst |

Brigitte Angres |

Christine Blechschmidt |

Alex Abramov |

Cellendes offers a hydrogel technology that comprises synthetic or non-animal derived defined components that enables the researcher to design extracellular environments for 3-D cell culture. Gels can be adapted in stiffness and biomimetic functions for specific (cell culture requirements) cell types, cell co-cultures, and multicellular structures. Areas of application are basic research, cell-based assays and in vitro tissue models. Founded in 2009 by Dr. Brigitte Angres and Dr. Helmut Wurst, Cellendes manufactures and commercializes hydrogels for 3-D cell culture since 2010. Cellendes’ hydrogel technology offers an extraordinarily high flexibility in gel composition and manipulation of physical gel properties. It comprises synthetic or non-animal derived defined components suitable for the development of therapeutic products.

Cellendes is a privately-owned biotechnology company founded in 2009 by Dr. Brigitte Angres and Dr. Helmut Wurst. It is a spinoff of the NMI Natural and Medical Sciences Institute at the University of Tübingen (NMI), where the founders developed Cellendes’ core technology. The company specialises in the development of biomimetic hydrogel systems for three-dimensional cell culture with expertise in:

• chemical modification and purification of proteins and polymers as components for hydrogels for 3-D cell culture systems,

• design of peptides as factors for controlling cellular phenotype in 3-D cell culture systems,

• development of 3-D cellular assays.

Furthermore, Cellendes has expertise in chemical, biochemical, as well as molecular biology assays.

Cellendes manufactures and commercializes hydrogels for 3-D cell culture since 2010. Cellendes’ hydrogel technology offers an extraordinarily high flexibility in gel composition and manipulation of physical gel properties. It comprises synthetic or chemically defined components suitable for the development of therapeutic products.

Role in the project

Cellendes will optimise and formulate hydrogel reagents and compositions for the photo-inducible bioink development which will be applied in the three tissue models skin, cornea and intestine.

TECHNION – ISRAEL INSTITUTE OF TECHNOLOGY, Israel

SENATE BUILDING TECHNION CITY, Haifa 32000

Department carrying out the proposed work:

Genetics & Developmental Biology

1 Efron Street, 31096 Haifa, Israel

Person in charge of the proposal:

Ruby Shalom-Feuerstein · shalomfe@technion.ac.il

Group leader, Genetics & Developmental Biology department

|  |  |

| Ruby Shalom-Feuerstein Principal Investigator shalomfe@technion.ac.il | Anna Altshuler Postdoc anna.altshuler@gmail.com | Aya Amitai-Lange Research associate and lab manager langeaya@gmail.com |

The Technion – Israel Institute of Technology has been Israel’s primary technological university and the largest centre of applied research. It is ranked among the leading technological universities in the world (32nd for Technical Sciences, 33rd for Natural Sciences from the ‘QS World University Rankings 2009). Many innovations in all fields of science, technology, engineering and life sciences have their origins in research conducted at the Technion. Technion researchers have won many prestigious international awards over the years, including three Nobel prizes awarded to Technion researchers in the last decades; the Chemistry Nobel prize awarded to distinguished professor Dan Shechtman in 2011, for the discovery of quazi-crystals and the Chemistry Nobel prize In 2004 to Distinguished Professors Avram Hershko and Aaron Ceichanover, for their pioneering research on degradation of intracellular proteins. Within the Technion, the RS-F group, headed by Prof. Ruby Shalom-Feuerstein is focused on the study of fundamental and translational research of skin, corneal and pluripotent stem cells. They developed pluripotent stem cell disease models for skin/corneal congenital pathologies and discovered potential therapy by small molecular weight compound that is now studied in clinical trial. They recently established new genetic mouse models for tracking stem cell dynamics in living animal, addressing the control of disease causing genes on stem cell function. Moreover, the group has established several fruitful collaborations at the national and international level, including, Prof. Nathan Karin, Yaron Fuchs, Prof. Carmit Levy and Dr. Chen Luxenburg (Israel), Prof. Gerry Melino and Prof. Caterina Missero (Italy), Prof. Colin Willoughby (UK), Prof. Daniel Aberdam and Prof. Chloe Feral (France), Prof. Matthew Poy (Germany), Dr. Yoel Kloog (Tel Aviv University) and more.

Role in the project

RS-F group has large expertise in stem cell biology with special emphasis on skin and corneal stem cell research. They will be in charge of sharing the knowledge of stem cell culture and providing the cellular models, scientific knowledge about stem cell biology and collaborate on the fabrication and testing of the new engineered tissues using the biomaterial scaffold to be developed by the bio-engineering experts. As IBEC, TECHNION will be part of the showcase of the developed B-BRIGHTER light-sheet bioprinter, testing its applicability, in this case, for developing skin and cornea models.

Only members of the B-BRIGHTER PROJECT consortium may have access to this intranet. Please request access to the project coordinators.